Lime slurry can be an unforgiving material to pump because it is inherently abrasive corrosive has high particulate and high viscosity. Any design should assume that and provide for back-flushing of the nozzle or dilution of the slurry by having a side port where liquid from the top of the tank can be injected into the nozzle.

Is Lime Souring Your Valve Operation

A rotating atomiser is used situated in the top of the spray-dry chamber.

. The financial ramifications of improper valve instrumentation and piping selection for processes such as lime slurry can have a long-term negative impact on most operations. One advantage of the process is the lack of serious material corrosion problems. Every change of direction adds friction losses to the flow.

For example when primary sludge is drawn from clarifiers it is sometimes by gravity and sometimes by direct suction using pumps. Lime Slurry Piping Reduces Westar Plant Downtime July 9 2013 in Blog by theVR. If this wears or suffers blockage the spray pattern is affected which reduces further the desulphurisation efficiency.

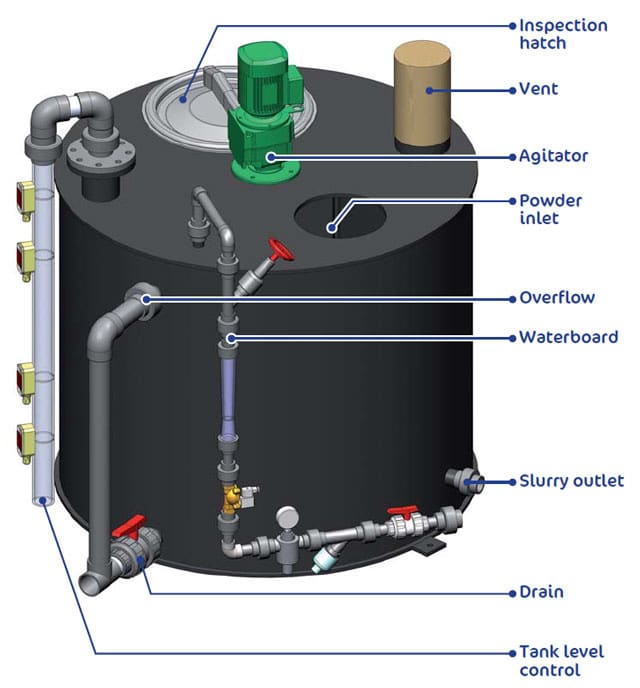

Guideline and Manual for Planning and Design in Japan JSWA 2009 62 HYDRAULICS OF SLUDGE PIPELINES 621 Sludge Piping Sludge piping can be by gravity or by pumping. - with water is often called a slurry. Probes used for level control in the slurry tank are often coated with lime solids and rendered ineffective.

Specialized valves can minimize the buildup in the nozzle but aren t foolproof. Size slurry piping with a min velocity of 2 fps and max of 4 15 ypp g y p fps. Tanks made of corrosion resistant metal should be used to avoid abrasion problems.

If this wears or suffers blockage the. Slurry can be described as liquid with solids suspended therein. Lime slurry would be one of the most difficult fluids to work with.

Inlet Design for Lime Slurry Applications. In transport systems for slurries its important to avoid settling of solids by keeping the fluid velocities in the pipe lines. Slurry piping system like any other system consists of slurry pumps pipelines and valves.

Piping systems can take many forms from overland pipelines to mineral processing plants coal washeries and the like. Inlet Design Hints 1. Tomato juice is 180 cps Size metering pumps with a 301 turn-down.

Mechanical agitation is provided to promote hydration by continuously exposing lime particles to moisture. I have also seen a half pipe PVC_U used in a gravity situation. The lime slurry is hauled to the roadway and placed via special slurry tanks with agitators to keep the lime in suspension during transport and placement.

INPIPE PRODUCTS was approached to look at progressive cleaning of an 8 mine slurry pipeline used for transporting rock waste with water and cement to refill areas of the mine following ore extraction. Material buildup on valve seats and other surfaces can cause the valves to freeze in position. After some time in operation it was determined that there were areas of high wear in one of the 8 inch fiberglass pipe lines at some of the elbow locations.

One of the many advantages of working with fiberglass is its versatility. On-site preparation of high-density slurry concentrations ranging from 32-38 eliminates the need for costly delivery of lime in slurry form HDL Slurry remains in suspension drastically reducing scaling build-up in pipe and equipment HDL reduces operator maintenance and equipment downtime. Browse Our Slurry Pumps Contact Us For a Quick Quote.

Maintain the inlet line in as straight a run of piping as possible. In order to replace the worn elbows. Transportation of bulk materials in the form of a slurry through piping systems is a most efficient and effective mechanism.

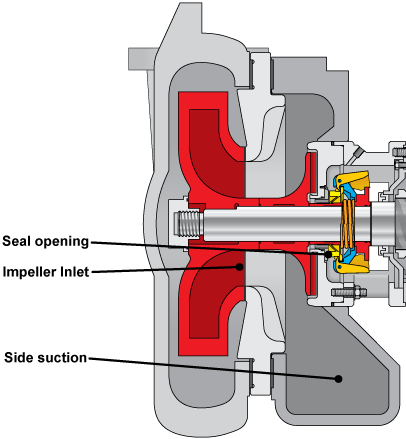

Design Conditions 150 PSIG 149oF Operating Conditions Atmospheric - 125 PSIG 110oF Design Fabrication Installation Approval Requirements ASME B311 Power Piping OReg. Kpro K and HD are all designed with their suction on the side of the pump and with the. Specifics - High density lime 35 35 slurry acts as a pseudo plastic and will not settle or scale pipelines 35 slurry has a viscosity of 200 cps.

The lime changes its state to a solid mass of material commonly referred to as scaling. Slurry piping system like any other system consists of slurry pumps pipelines and valves. Pigging of Slurry Pipeline.

Below ground refill being substantially less. This Manual sets out the basic principles and gives a good appreciation of the technology. PO Box 536 730 Superior St Building 16 Carnegie PA 15106.

Abrasion resistant fiberglass pipe was chosen to move the limestone slurry within the system. Lime Slurrying A severe problem of abrasion occurs if fiber rein- forced plastic FRP tanks are used for slurry pre- paration. A straight line from tank to.

Chemco hydrated lime systems are able to produce a wide range of lime slurry concentrations from 5 concentration up to a high density concentration greater than 375 to meet the application requirements. Mechanically the design of the lime-slurry spraying equipment is important. Sufficient detention time must be allowed in the basin or scale will form on the surfaces of downstream units and piping.

The half pipe was run over the sedientation tank. The limestone is abrasive and requires an abrasive resistant piping system. Maintain the inlet line in as straight a run of piping as possible.

Posted by vickyadmin September 19 2018 September 30 2021. Reduces cost of lime supply. This was for lime dosing in a sewage treatment.

Classes of Construction see Standard Specification Section 225 1. This was for lime dosing in a sewage treatment plant. Lime is applied in 2 applications.

Size slurry piping with a min velocity of. Flow velocities in slurry transport systems to avoid settling of solids. 22001 Piping systems are not subject to the approval of TSSA Boilers and Pressure Vessels Safety Division.

Class A- Used for extremely poor soils PI 45 to 50. The EDDY Slurry Pump was designed to excel in the harshest applications and makes it a superior. Wilfley Kpro K and HD slurry pumps are very commonly used in lime slurry applications.

Learn how the EDDY Pump is a top choice for lime slurry pumping. Special considerations relevant to this systems are introduced by the fact that slurry in not homogeneous phase unlike gas or liquid. Lime Slurry - Up to 150 PSIG.

If a higher degree of accuracy is required Chemco also fabricates a. Scaling causes a pipelines inner diameter to become smaller and smaller. The lime slurry formed overflows into the second compartment where the slaking process is completed.

Their unique design makes them almost perfect for this duty but care must be taken in the inlet design to ensure proper operation. Lime slurry is a stable suspension and is not corrosive once the slurry has been stabilized by allowing all of the water to fully react with the calcium hydroxide usually about 15 minutes minimumThe dissolved solids from the dilution water will precipitate if injected before stabilization on piping and injectors and form scale. When utilizing a Chemco volumetric screw feeder concentrations are achieved within -20.

Fiberglass can be used in abrasive and corrosive applications but it can also be used to create custom parts to fit almost any need. A suspension of solid particles in a liquid as in a mixture of cement clay coal dust manure meat etc. Inlet Design Hints 1.

Design the inlet piping to be as short as possible between the sump and pump. We worked with Westar Energy to identify problem.

Rdp Tekkem Precision Hydrated Lime Systems Lime Silo Precision Dosing Assembly Rdp Tekkem System Controls Lime Slurry Piping Lime Slurry Pump Slurry Ppt Download

Lime Slurry An Overview Sciencedirect Topics

Inlet Design For Lime Slurry Applications Wilfley Durable Waterless Sealing Industrial Pumps

Dilution Tank For Preparation Of Lime Milk Or Carbon Sodimate

0 comments

Post a Comment